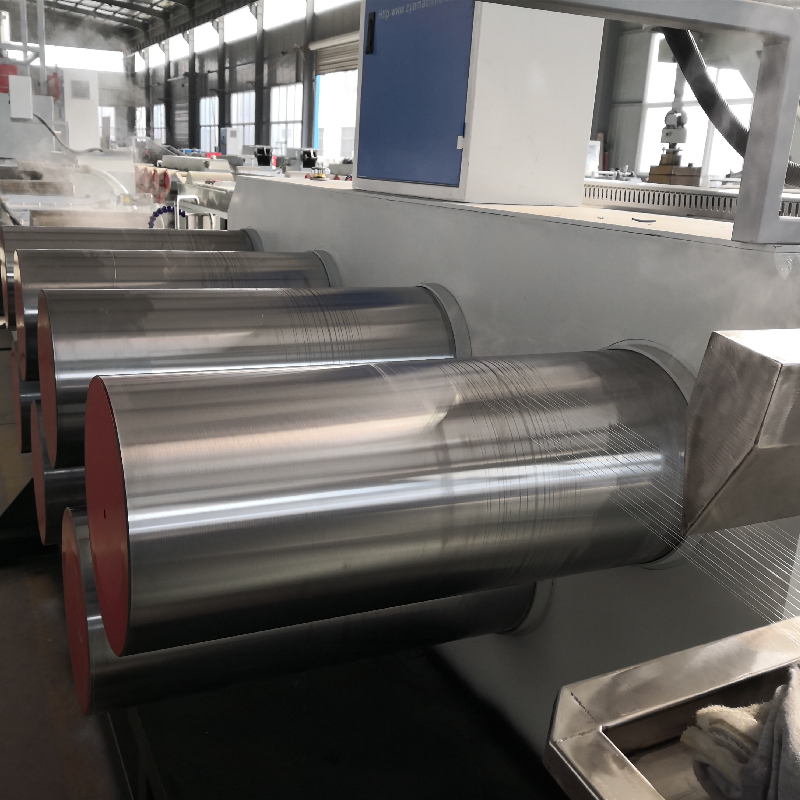

Raws li qhov xav tau sib txawv ntawm Nylon txhuam hniav fiber ntau zoo, peb ua cov tshuab sib txawv tsim rau peb cov neeg siv khoom. Peb tsim cov cua kub tshwj xeeb rau lub tshuab kab uas tuaj yeem ua kom zoo elasticity ntawm cov txhuam hniav fiber ntau. PBT txhuam hniav fiber ntau yog muaj zog alkali tsis kam, muaj zog acid kuj, zoo dua puas thiab resilience, tsis tshua muaj noo noo nqus, thiab muaj zog resilience. Nws yog dav siv rau cov khoom siv txhuam hniav.

Hluav taws xob system: Lub cev muaj zog yog SHANGHAI ZHONGTIAN thiab inverter yog ABB; AC contactor thiab thermal overload relay yog qhov tseeb SIEMENS; Kub maub los thiab mus txawv tebchaws yog Nyiv OMRON.

Rau cov yas txhuam hniav filament extruding tshuab kab, peb tsuas yog muab cov qauv hauv qab no raws li cov khoom siv raw khoom thiab cov txheej txheem yuav tsum tau ua.

> > Model Parameters

| Qauv | TSI-65 | |

| Ntsia Hlau L / D | 30:1 ua | |

| Gearbox qauv | 200 | |

| Main lub cev muaj zog | 18 kwv | |

| Peev xwm (kgs / h) | 30-90kgs / h | |

| Pwm Dia. | 200 | |

| Filament Hnub | 0.08-0.35 hli | |

| Tshuab Kab General Configuration List | ||

| Tsis muaj. | Lub npe tshuab | |

| 1 | Ib leeg ntsia hlau extruder | |

| 2 | Tuag lub taub hau + spinnerets | |

| 3 | Dej trough calibration system | |

| 4 | Tensile unit | |

| 5 | Lub tank dej kub | |

| 6 | Tensile unit | |

| 7 | Lub tank dej kub | |

| 8 | Tensile unit | |

| 9 | Roj txheej tshuab | |

| 10 | Winding tshuab | |

| 11 | Calibration qhov cub | |

> > nta

1. Haum rau zoo nylon txhuam hniav filaments ntau lawm

2. Customized txhuam hniav filament loj thiab xim

3. Customized tshuab kab configuration kom tau raws li cov kev cai sib txawv

4. Mature ntau lawm txheej txheem kev txhawb nqa

5. Ntau lawm kab tsim raws li exsiting Rhiav loj ntawm cov neeg siv khoom

6. Qulified fiber ntau lawm nrog zoo softness thiab elasticity assurance

7. Ib-nres kev pabcuam los ua kom cov neeg siv khoom tau txais txiaj ntsig

8. Ua tau zoo debugging nrog tsim nyog PA txhuam hniav fiber ntau

>> PA Nylon txhuam hniav fiber ntau extruding tshuab

Q: Puas yog koj lub tuam txhab tsim khoom lossis tuam txhab lag luam?

A: Peb yog cov chaw tsim khoom.

Q: Peb puas tuaj yeem xa cov qauv rau kev kho lub tshuab kab?

A: Yog lawm, peb yuav tsim thiab muab cov tshuab customized raws li koj cov qauv.

Q: Peb puas tuaj yeem tuaj xyuas koj lub Hoobkas kom pom cov kab ntau lawm?

A: Yog lawm, peb tuaj yeem npaj koj kom pom peb cov kab ntau lawm kom nkag siab zoo dua ntawm peb cov kab tshuab.

Q: Yog tias peb muaj teeb meem ntawm lub tshuab khiav, peb yuav daws nws li cas?

A: Peb muaj kev pabcuam kev pabcuam tomqab muag uas yuav pab koj daws teebmeem hauv lub sijhawm.